The project name:Steel structure aircraft test guide wall repair and reinforcement project.

Demand for the unit:Guangzhou aircraft maintenance engineering co. LTD.

Project technical requirements:

The technical requirements for guangzhou aircraft maintenance engineering co., LTD. According to the actual production requirements, including but not limited to the following technical standard, manufacture and design standards should be consistent with the People's Republic of China civil aviation industry standard MH/T3012.17-2010.

The basic requirements:

1. Applicable model: all narrow-body and wide-body aircraft.

2. Air flow diversion and noise reduction function of the aircraft test fan type guide wall: 98% of the tail flow is directed to the air: the wind speed of the engine in the wall is 50m/s, and the wind speed is 1.5m/s at 10m outside the wall, which is the natural wind speed. The noise of engine noise in the wall is about 140 decibels and the noise outside the wall can be reduced to 70 to 85 decibels. Outside the wall is the safe area, the rear wall 10 meters outside the vehicle can drive, the personnel normal work.

The technical conditions of the fan-shaped guide wall of the aircraft.:

1. The pilot wall of the aircraft test vehicle can withstand the engine thrust of the B777 aircraft by 115,000 pounds and 1.5 times load.

2. The safety level of the guide wall structure is secondary.

3. The service life of steel structure is 50 years.

4. The guide wall can be used for more than 15 years.

Comprehensive information of the pilot wall of aircraft ground test.:

1. Composition of special curved steel structure with air flow guide wall:

Shape: u-shaped, arc wall length 7.2m, vertical height of 5.78m.

2. Composition of composite modules; Stainless steel micro-orifice/waterproof flame retardant absorbent cotton/cavity layer/sound insulation rubber sheet/galvanized color steel plate.

3. A joint brand chemical anchor is used for the connection of the front beam/rear pillar/reinforced post and the apron.

4. The connection of steel components is made of 8.8-level galvanized high-strength bolt, and the fastener is made of stainless steel.

Warm congratulations to the GAMECO aircraft for the enhancement and restoration of the diversion wall of the noise diversion wall.

On November 30, 2017, shenzhen yiu sky technology service co., LTD., guangzhou baiyun international airport GAMECO aircraft test noise reduction post-embedded diversion to strengthen and repair engineering, the B777 aircraft wide-body jet blow after verification, the noise reduction diversion effect and structural strength to meet the design requirements, project a complete success and one-time acceptance through! Because there are company team cooperation and coordination of customer, make the project research and development of complete design and implementation of the scene at a predetermined period, to fight for this project the thirty days in this team mates expressed warm congratulations, and hope that our team in the national airport play more!

Aircraft maintenance finished, and then to aircraft engine test, by the shenzhen yiu sky technology service co., LTD., independent research and development production of aircraft ground test diversion and noise reduction facilities, in 2015, has applied for patents, patent number: ZL201520269053.3. The product has advanced technology, strong structure and so on. To be able to conduct airflow direction and noise reduction during the test. This for GAMECO to provide technical services for the diversion of strengthening and repairing, involving stainless steel design and manufacture of microperforated panel and sound insulation cotton and sound-absorbing cotton and cavity layer structure design and installation, to 90 ~ 95% of the airflow direction air effectively, the noise of the engine run 35 ~ 45 decibels, achieved the desired design effect.

Developed by our company in May 2017 day yao qi civilian aircraft ground test diversion and noise reduction facilities WEB side control management software [soft zhao's words] no. 2197285 will be at the airport, it can be according to the configuration of electronic control system, solar lighting system, real-time display alarm test site of environmental wind direction, using parameters such as frequency and related data, and can pass the APP download data to the background monitoring system, always keep the factory tracking equipment usage.

Shenzhen yiu sky technology service co., LTD., the diversion of aircraft ground test and noise reduction facilities products through the national many aircraft maintenance companies and use of the airport, it is proved the reliability and stability, but yao day's technical team is still unremitting effort for the user experience and the quality of the products, sure yao day's products can help to provide more customers!

The following is the implementation process of the project.:

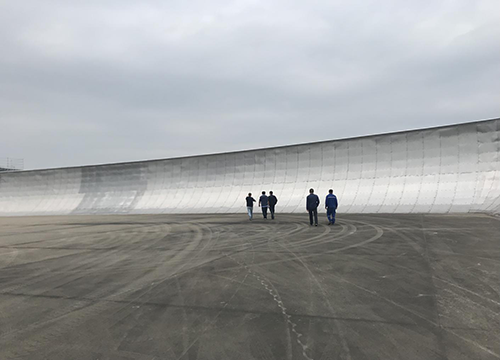

Project implementation site

Project implementation site

Project implementation process

The construction site of the GAMECO aircraft test vehicle is enhanced and repaired.

The construction site of the GAMECO aircraft test vehicle is enhanced and repaired.

The construction site of the GAMECO aircraft test vehicle is enhanced and repaired.